HIGH-PERFORMANCE ABRASIVES

High-performance abrasives from WEFRA

WEFRA was founded in 1929 as a family business, initially focused on talc mining and granite trading. WEFRA developed and produced its own cutting discs for granite processing, laying the foundation for the production of high-performance abrasives, which began in 1955 – making it one of the first manufacturers of such products in Germany. In 2025, the company was acquired by the STELLA GROUP and relocated to its new headquarters in Schwarzenbach/Saale. The highest product quality, reliable service, and market-oriented product development remain central to our business strategy.

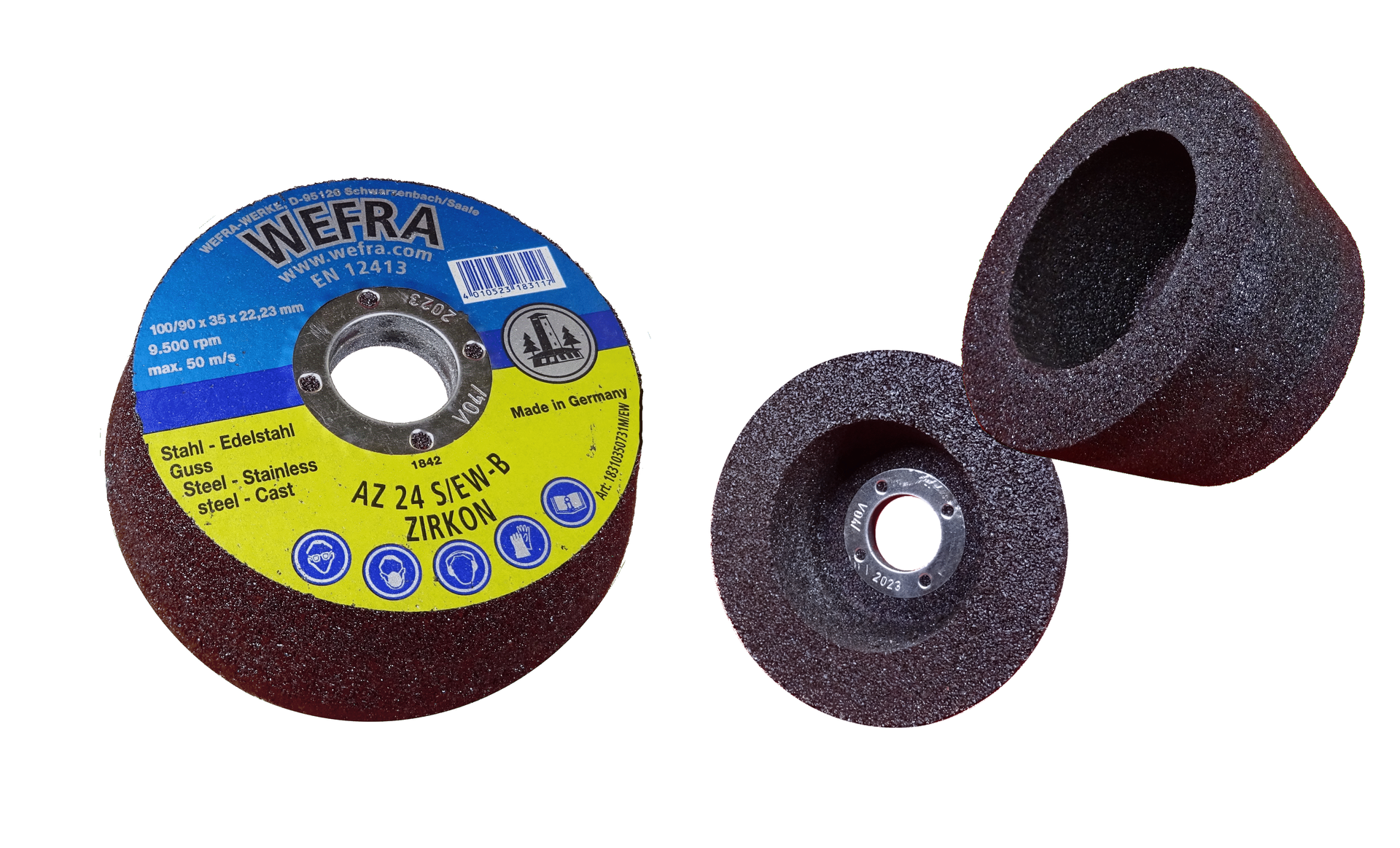

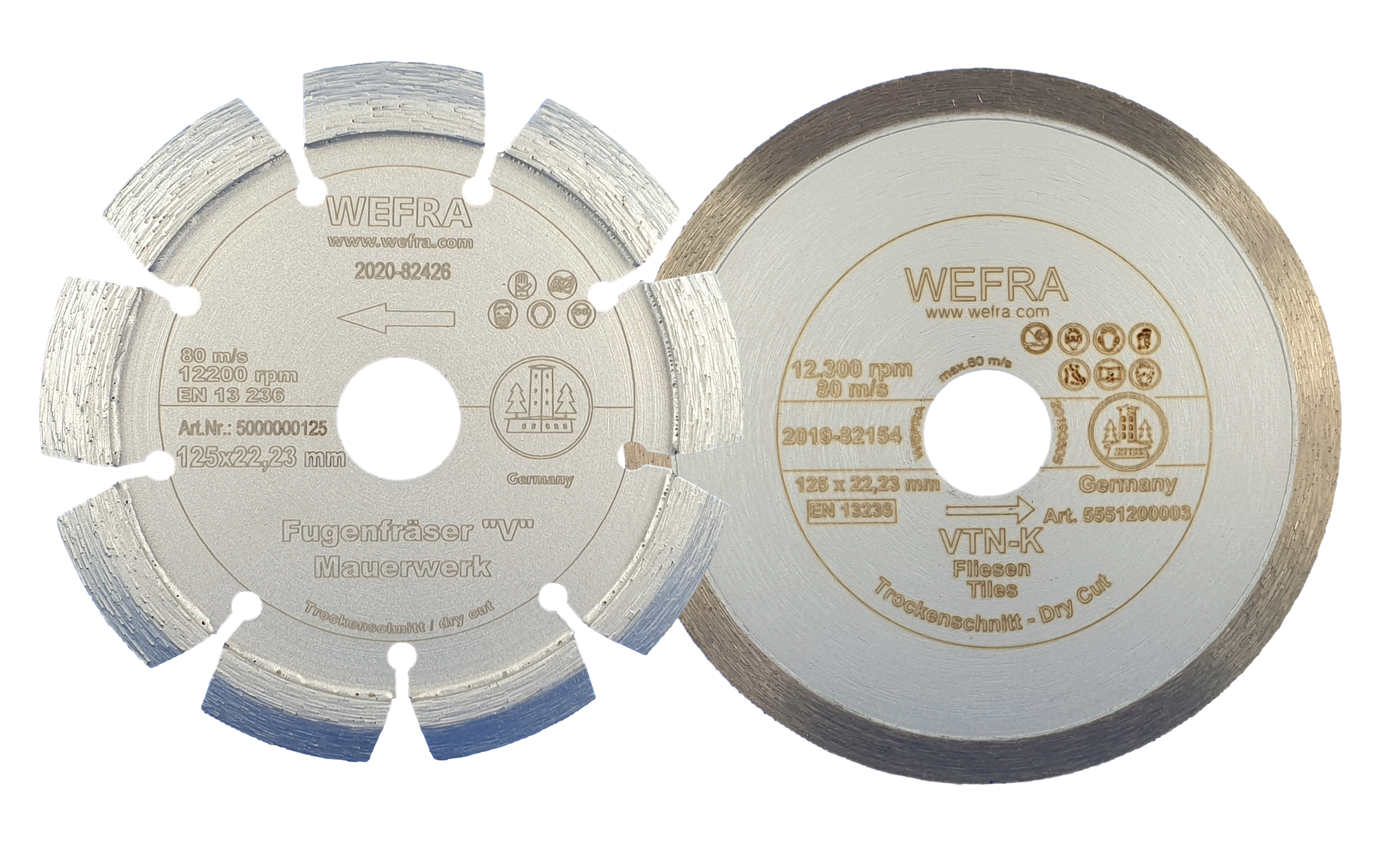

Our product portfolio includes the following categories:

quality and safety

Controlled quality

Our primary goal is to manufacture and distribute safe, high-quality grinding tools that prevent accidents. In doing so, we send a clear message against inferior and dangerous products. For maximum user safety, we manufacture according to the world's strictest guidelines and monitor the safety and quality of our products in accordance with the latest standards, regulations, and norms. We hold our suppliers to the same high standards. Our internal quality management system ensures that we, as a modern, globally operating industrial company, meet the high demands we place on ourselves at all levels.

SAFETY FIRST

Safe handling of abrasives

Freehand grinding and grinding with stationary machines are central processes in metalworking for shaping or surface finishing. Depending on the application and the abrasive used, different risks can arise. Grinding processes are subject to high speeds and temperatures. A freely rotating grinding wheel on an angle grinder typically accelerates to up to 13,200 revolutions per minute. This results in speeds of more than 186 mph (300 km/h) and process temperatures of more than 800 degrees Celsius at the edges. As with all industrial processes, human error or equipment malfunctions can lead to safety problems, burns, or cuts. In addition, there are potential health hazards such as noise, dust, or excessive hand-arm vibration.

We are constantly developing our products, not only to increase their efficiency but also to reduce the risks associated with grinding. Every WEFRA product includes relevant safety instructions that you must follow to ensure the safe use of our grinding products. Information on the safe use of grinding tools and informative application videos can be found at the following link: